Pressure Pulsation Test Stands up to 6,000 bar

Pressure Cycle Test Bench | Impulse Test Stand | Automotive Testing | Testing with Coolant, Oil, Water and more

The Poppe + Potthoff impulse test stands test the operating or fatigue strength of various metal and plastic components. The endurance test in our high-pressure test systems simulates the life-cycle under varying loads. The failure tests thus show the potential weaknesses of the components with respect to design and material. The pressure is optionally modulated as a sine wave, trapezoid curve or needle pulse. Our test stands are characterized by a special ergonomics and are designed by Poppe + Potthoff machine design. Due to our flexible modular design, our machines are very variable, so that the pressure and volume range is designed according to the customer’s requirements. Of course, our systems are UL or CE compliant as required. In addition, we offer you service and support directly on-site.

Varying pressure

The pressure can be controlled very precisely by means of servo hydraulic pressure boosters that are optimally designed for the test area desired by the customer. It can vary depending on the frequency and impulse volume, or it can remain constant for long-term tests or can be increased to bursting point.

Applications

- Impulses from 0 to 6,000 bar at a frequency of up to 30 Hz

- Testing the operating and fatigue strength of high-pressure components

- Stress tests in research and development, as well as on a series-basis

- Sine and trapezoidal test curves

- Needle pulses in 5ms

Services

In general, we also offer pulse testing in the relevant pressure and frequency ranges as a service. Whether for research and development or for once-in-a-lifetime tests, please contact us with your test requirements for a non-binding offer.

For different impulse tests, click on the following application areas:

The impulse pressure is generated by a pressure booster with a hydraulic drive. A hydraulic power unit generates a constant hydraulic pressure of 350 bar. This pressure drives the pressure booster via a regulator valve. The pressure booster has a constant pressure boosting ratio and produces the high pressure due to its linear movements. A highly dynamic servo regulator valve is used as the regulator valve, which allows very high test frequencies with precise repeatability. The test pressure profile is measured and stored with a pressure transducer. These records allow the quality of the test to be assessed later. The pressure-control system of the plant also operates via this pressure sensor. The test medium is hydraulic oil. A perfectly tuned cooling system keeps the temperature at the pressure booster and in the hydraulics in equilibrium. Cooling is a very efficient water cooling system. Visualization of the test sequence is carried out via a PC. The operation is menu-driven and enables special software configurations. The system is self-monitoring. Possible faults are displayed on the monitor and lead to the system being switched off. Test failure is detected via an oil mist sensor. If an automatic shutdown occurs, an info message about telecommunication is sent to a mobile phone. All data relevant to the test is preserved, of course, and is automatically saved.

Performance data:

- Pressure booster for additional supply

- Temperature-controlled head-cooling

- Easy access to pressure booster

- can be converted to various pressure ranges (600 bar, 1,500 bar, 3,000 bar, 4,500 bar, 6,000 bar)

- Digital communication within the system

- Camera-monitoring of the test object and the cables

- LabVIEW application is self-extensible

- Separate controller parameters for each part of the load group

- Separate recording of statistical data of the upper and lower actual values

Application areas:

- Research and Development

- Accompanying endurance test of serial parts

- Automotive suppliers

- Optimization of assemblies

- Common Rails

- Injector Nozzles

As in the high pressure range of up to 6,000 bar, the standard impulse test stands are also operated with a hydraulic pressure of 330 bar. This is produced by a hydraulic power unit and drives the pressure booster via a regulator valve. The pressure booster has a constant pressure ratio and produces high pressure through its linear movements. We also use high-dynamic servo-regulator valves for our standard systems, which guarantee a precise repeatability even at very high test frequencies.

The pressure control of the system is realized by means of a pressure transducer. The test medium is hydraulic oil. A perfectly-tuned cooling system keeps the temperature at the pressure booster and in the hydraulics in equilibrium. The cooling is realized by a very efficient water-cooling system.

In order to be able to assess the quality of the tests, the test pressure profile is measured by the pressure transducer already mentioned and is accordingly stored in the system as a data record. The visualization and evaluation of the test sequence is carried out via a PC. The operation is menu-driven and enables special software configurations.

If necessary, it is possible to equip our standard impulse test stands in such a way that it is possible to switch to a different pressure range without great effort.

Application areas:

- Gasoline injector housing

- Pressure sensors

- Pipes and connectors

Technical specifications

- Impulse pressure: 1,000 bar / 2,000 bar

- can be converted to different pressure ranges (600 bar, 1,500 bar, 3,000 bar, 4,500 bar, 6,000 bar)

- Pulse shape: sine-wave, trapezoid curve or needle pulse

- LabVIEW application self-extensible

- Max. Test frequency: 15 Hz

- Test medium: hydraulic oil ISO HLP 46

For impact testing with subsequent long-term pressure and bursting tests, our systems offer two chambers in which up to ten tests can be done simultaneously at an ambient temperature of -60 °C up to 180 °C or at room temperature. Via separate control circuits, the medium Glykol is added to 100% or different oils – with a temperature from room temperature up to 160 °C. This makes it possible to carry out tests at very large differences in temperature, which are rare in real-life situations, even with curing tests on the Nürburgring, in the Siberian tundra, or in the deserts of Africa.

Various servo-hydraulic pressure boosters, which are optimally designed for each test area, allow very precise control of the pressure. Pulse-pressure tests can be performed with a frequency of 0 – 10 Hz (the norm is 0.5 – 2.5 Hz) with a trapezoid curve of 4 – 25 bar and 0 – 160 bar; In the sinusoidal curve with a frequency of 0 – 10 Hz, pressures of 0 – 6 bar are possible. The maximum burst pressure is 500 bar. Data acquisition and visualization is performed using National Instruments’ LabVIEW applications. All test sequences and data are automatically stored on the plant and can be exported to the network for evaluation.

Performance data:

- 3 different load change tests

- 3 different media (each with double tank system)

- additional burst pressure test: up to 500 bar

- additional leak test: up to 100 bar (long-term test)

- Frequency: 0.5 to 2.5 Hz (up to 10 Hz)

- Media temperature: RT up to +160 °C

- Ambient temperature: -60 °C to +180 °C

The combination systems are used to test coolers, engine and transmission components. The tests carried out are impulse tests with gear oil or coolant as well as burst pressure tests. The system is equipped with a test circuit for each test. Each test circuit is operated with a separate medium. The permissible impulse burst pressure depends on the test results. The tests can be carried out in a medium temperature of up to +135 °C RT. The system is self-monitoring in operation. Disturbances are indicated on the monitor and by means of the signal lamps and lead to a shutdown of the system. A test failure is detected automatically.

Key Features:

- Compact test system

- PPM design

- High dynamics

- Exact repeatability

- Media & ambient temperature control

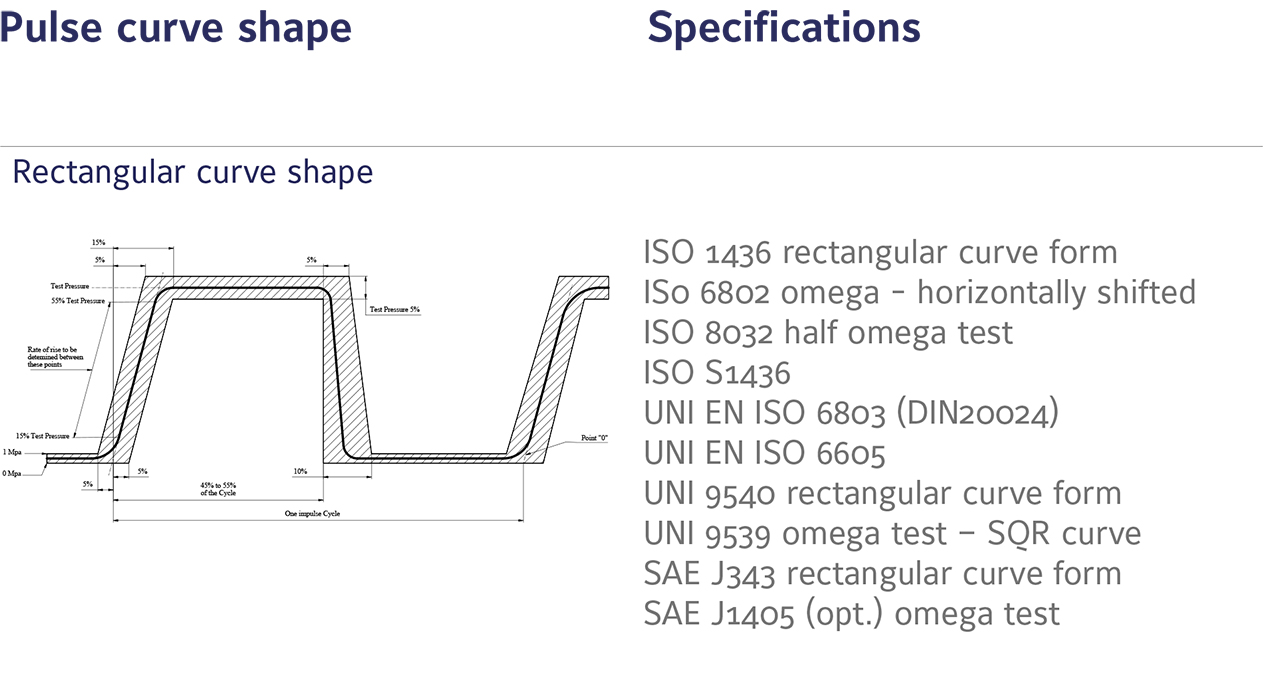

The PPM 432 can change the pressure in up to 100

load steps per minute and sets pulses with a frequency

of 0.2 Hz to 5 Hz. The test curve is usually controlled

with a sinusoidal or trapezoidal curve. But also pressure

holding tests and individual pressure curves with

10 points can be performed. Thus, all common test

standards, such as ISO, UNI, SAE, ARP or MIL, can be

flexibly fulfilled.

The test stand is operated via an internal programmable

logic controller (PLC) and a panel PC directly at

the machine. The integrated LabView software from

National Instruments enables efficient data acquisition

and visualization. All test procedures and data are

automatically stored by the system and can be exported

to the network for evaluation.

The open software structure allows additional sensors

and data to be integrated during the tests. Poppe +

Potthoff Maschinenbau adapts each system individually

to the specific needs of the customer and also offers

numerous testing services, remote maintenance and

technicians on site.

Performance data

| Dynamic test pressure min. | 0 psi (0 bar) | ||||||||

| Dynamic test pressure max. | 1 x 1000 psi (70 bar) 2 x 4000 psi (275 bar) 1 x 6000 psi (414 bar) |

||||||||

| Curve shape | Sine | Trapezoid | Static | ||||||||

| Speciality | An individual pressure curve with a maximum of 10 points can also be set |

||||||||

| Frequency | 0.2 Hz-5 Hz | ||||||||

| Load steps | 1-100 per minute | ||||||||

| Media temperature min. | -40°F (-40°C) | ||||||||

| Media temperature max. | +320°F (+160°C) | ||||||||

| Ambient temperature min. | -58°F (-50°C) | ||||||||

| Ambient temperature max. | +320°F (+160°C) | ||||||||

| Ambient alteration speed | 1.5 K per minute | ||||||||

| Test chamber size W x D x H | 1500 x 900 x 900 mm | ||||||||

| Test medium | aerospace oil | ||||||||

| Number of test specimens max. | 4 (upon customer request) | ||||||||

| Flow rate per test specimen | 0-4 l per minute | ||||||||

| Performable tests | Pulse pressure test Pressure holding test |

||||||||

| Dimensions and weight |

|

Your request

Contact us

Johannes Montag

CEO

Frank Baudler

CTO

Philip Claussen

CEO

+49 3631 46221022

salesppm@poppe-potthoff.com

Philip Claussen

Poppe + Potthoff Maschinenbau America

+1 617 250 7668

philip.claussen@poppe-potthoff.com

For further testing solutions, click the following product areas:

Poppe + Potthoff Maschinenbau is part of the Poppe + Potthoff Group

18 locations in 9 countries.

Poppe + Potthoff Gruppe has 18 production plants and sales offices in 9 countries. The name Poppe + Potthoff always indicates the highest quality – a promise to which our customers rely on, regardless of which Poppe + Potthoff location they work in.